- Visit our CNC Machining & Laser Cutting Website:

- T2K CNC

- +44 (0) 121 242 2000

- sales@tooling2000.co.uk

Looking for end-to-end solutions for prototype manufacturing? We can turn your concepts into reality with precision prototyping and advanced techniques.

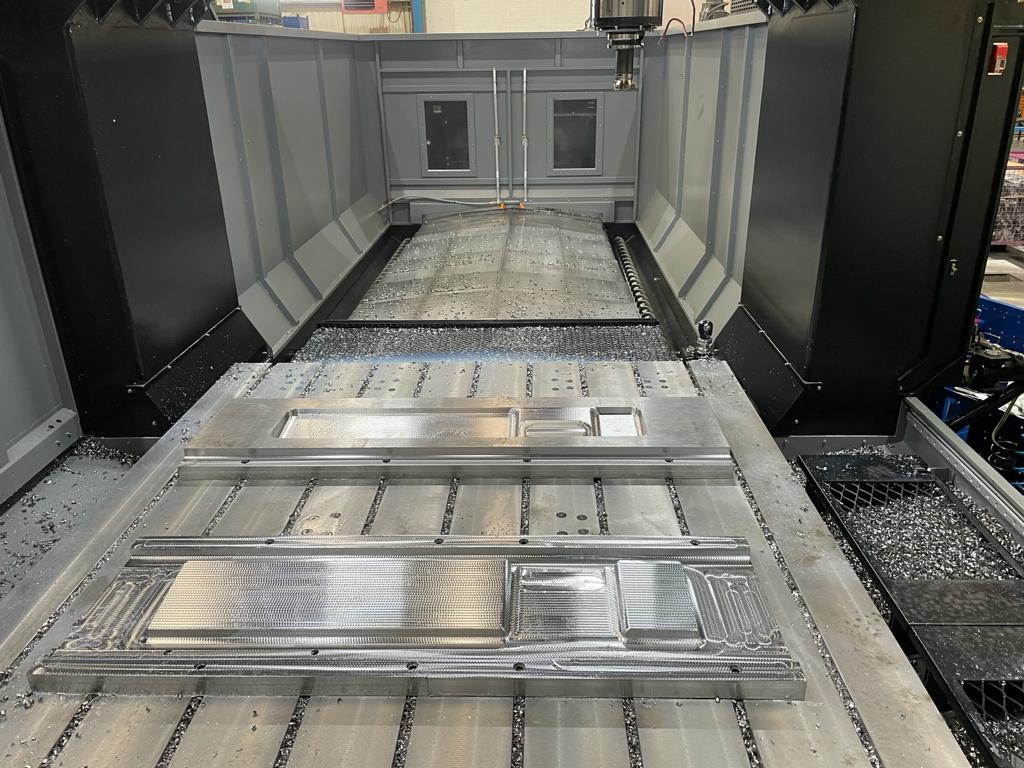

From initial design to the finished part, our expert team delivers unmatched quality and reliability. Based in our state-of-the-art Birmingham facility, we handle everything from small-scale prototypes to large industrial parts, ensuring your project exceeds expectations every step of the way.

With expertise in precision prototyping and a commitment to quality, we ensure each stage of the manufacturing process meets the highest standards. From initial feasibility testing to final production, we partner with you to deliver reliable results.

At Tooling 2000, we specialise in working with customers who need prototypes to test feasibility and functionality. Our team collaborates closely with you to formulate the best solutions, tailored specifically to your requirements.

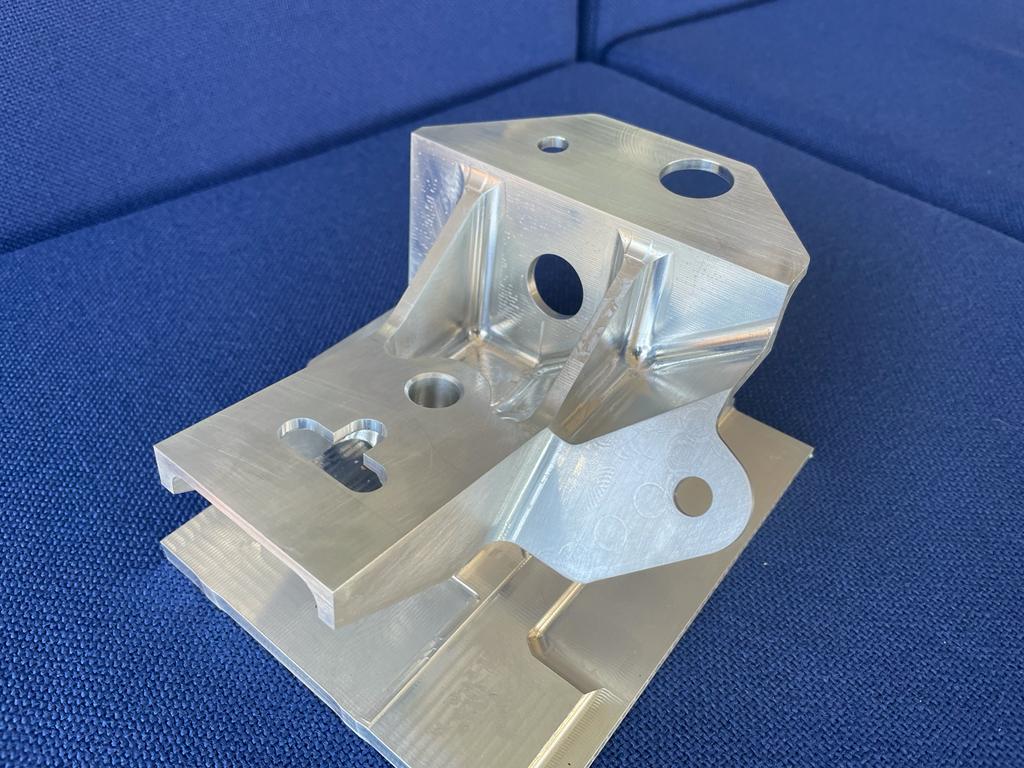

Yes. We can support prototype parts and early trials to help you validate form, fit, and key features before you commit to full production tooling. It’s a practical way to reduce risk and make sure the design is heading in the right direction.

A PDF drawing is a good start, and CAD is helpful if available. To quote and plan properly, we also need material and thickness (or your preferred options), quantities, required date, and any critical tolerances or quality requirements. If you are not sure, send what you have, and we’ll guide you.

Yes. We offer tool try-out and proving to check tool performance and part quality under real pressing conditions. This helps confirm repeatability, highlights any adjustments needed, and supports a smoother move into production.

Yes. Once the prototype is approved, we can progress into tooling manufacture and repeat stamping production. If any changes are needed after trials, we will advise clearly and manage the transition so you get stable, consistent output.

From first prototype to production-ready presswork

Got a part you need to prove? We support prototype parts, trial components, and prototype tooling & try-out – so you can validate fit, function, and manufacturability before committing to full production.

Send what you have – if anything is missing, we’ll help you fill the gaps.

41 Western Road Winson Green Birmingham B18 7QD

sales@tooling2000.co.uk

+44 (0) 121 242 2000

© 2025 Tooling 2000 Ltd | Registered in England No. 03273596 | VAT Reg. No. GB195384370 | Privacy Policy | Terms & Conditions