- Visit our CNC Machining & Laser Cutting Website:

- T2K CNC

- +44 (0) 121 242 2000

- sales@tooling2000.co.uk

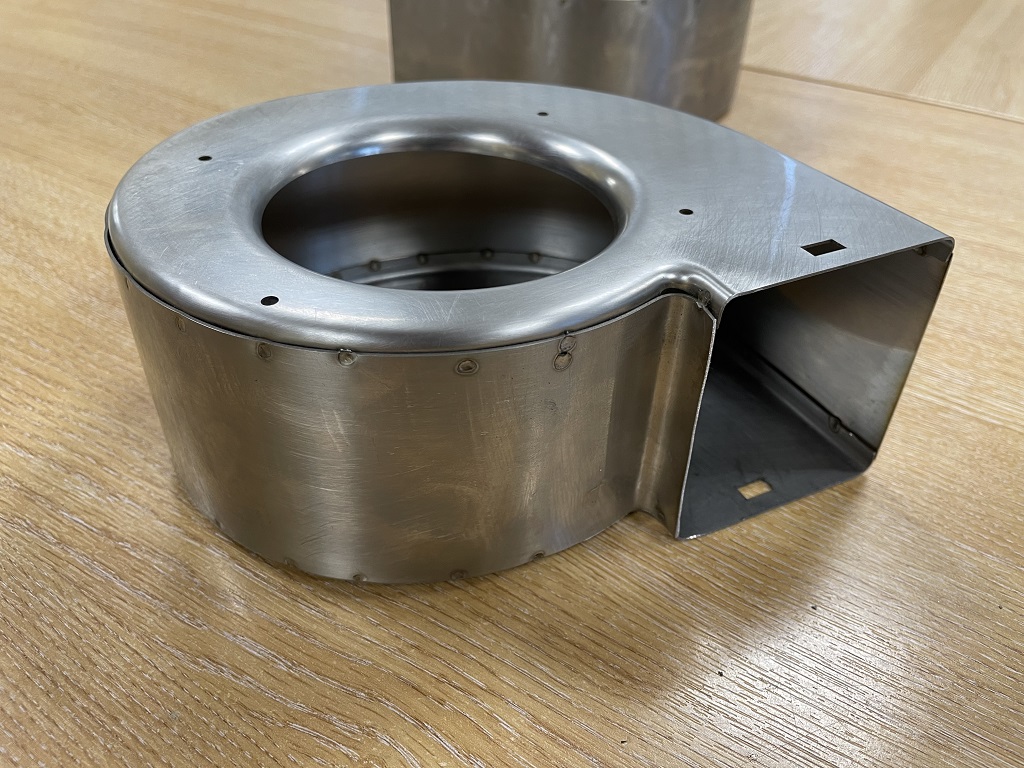

Tooling and stamping projects run best when the groundwork is done properly. Our Precision Tooling service helps you build tools that perform reliably in production, with repeatability, tool life, and part quality considered from the very start.

We take an engineering-first approach to every tool build, reviewing your drawings and requirements to confirm the right tooling route for the part, material, and expected volumes. If we spot risks that could affect performance later, we flag them early and recommend practical improvements. Once the approach is agreed, we design, build, and support tooling that’s ready to run, not just ready to fit.

Single operation tools complete one main action per press stroke. Tandem tools use multiple stages across separate tools to form the part step by step. Transfer tools move the component between stations, helping achieve more complex forming with better control and repeatability.

Yes. We design and manufacture progression tooling to support repeat production, especially where higher output and consistent part quality are required.

We produce tooling for blanking, forming, trimming, and progression work, and we advise the best approach based on your part geometry, tolerances, and expected volumes.

Yes. We can repair damaged tooling through reverse engineering, using our in-house scanning facility to recreate critical features and restore tool performance.

GET IN TOUCH

Got a tooling project? Let’s make it practical.

Whether you need a new tool build, jigs & fixtures, or tool repair/modification, our in-house toolroom team will review your requirements and come back with a clear next step.

Get in touch today – let’s turn your ideas into reality..

41 Western Road Winson Green Birmingham B18 7QD

sales@tooling2000.co.uk

+44 (0) 121 242 2000

© 2025 Tooling 2000 Ltd | Registered in England No. 03273596 | VAT Reg. No. GB195384370 | Privacy Policy | Terms & Conditions