- Visit our CNC Machining & Laser Cutting Website:

- T2K CNC

- +44 (0) 121 242 2000

- sales@tooling2000.co.uk

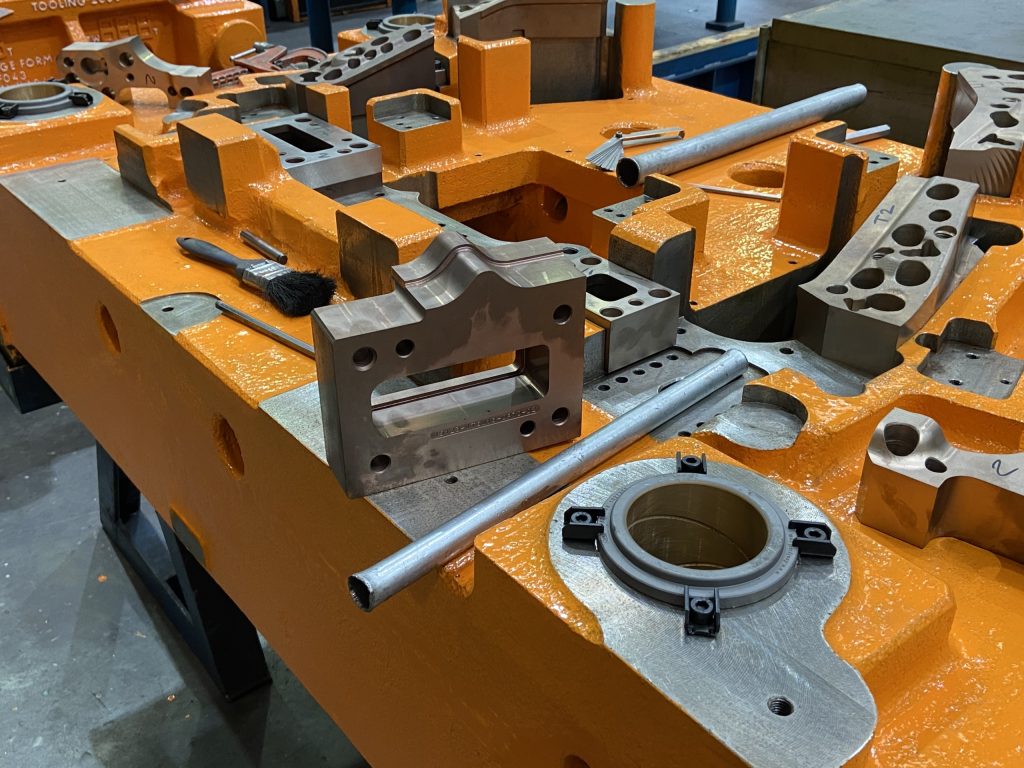

Tooling and presswork projects run smoothly when planning is done properly. Our Planning & Feasibility service helps you confirm what’s achievable, reduce risk early, and choose the right route before you commit to tooling or production.

We review your drawings and requirements with an engineering-first mindset—focusing on repeatability, tool life, quality, and delivery. If something could cause issues later, we flag it early and recommend practical changes. If the design is ready, we define the most efficient manufacturing approach and what’s needed to move into try-out and production with confidence.

Developing a new part can be a challenging time for any engineer.

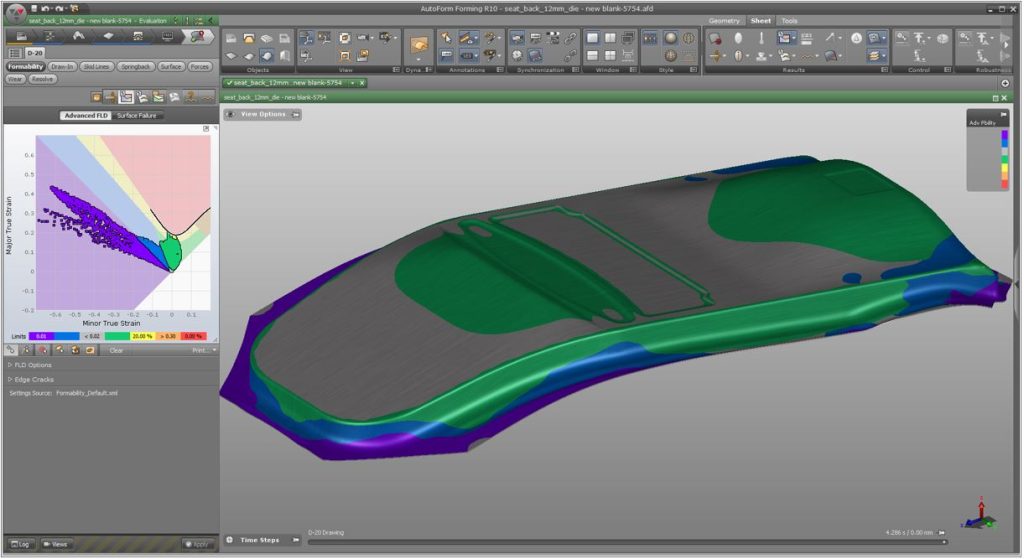

With the typical part becoming ever more complex and the choice of materials becoming ever more diverse, the ability to predict exactly how the material will react has never been so important. Having recently witnessed the results of a draw die manufactured without using simulation software our investment was soon proven to be worthwhile.

Within a few hours we were able to replicate all the split conditions the existing tool was producing and provide path to a solution.

Ideally, send a drawing or CAD file, material and thickness, quantity, and your required date. If it’s an existing tool or part, a quick note on any issues (wear, variation, downtime) helps us quote accurately.

Yes. We design and manufacture press tools in-house, which gives better control over quality, lead time, and long-term tool performance.

Yes. If drawings are unavailable, we can support reverse engineering to recreate or restore tooling features and help you get production back on track.

We work with common metals including stainless steel, aluminium, and brass. We can support low to high volume requirements depending on the part, tooling route, and production needs.

Lead times depend on complexity, material, and current capacity. Once we review your drawings and requirements, we’ll confirm feasibility and provide a clear, realistic lead time for tooling, proving, and production.

GET IN TOUCH

We make everything with a passion for quality

Whether you need assistance with feasibility or the CAD Design of Press Tools and Prototype Tooling.

Get in touch today – let’s turn your ideas into reality..

41 Western Road Winson Green Birmingham B18 7QD

sales@tooling2000.co.uk

+44 (0) 121 242 2000

© 2025 Tooling 2000 Ltd | Registered in England No. 03273596 | VAT Reg. No. GB195384370 | Privacy Policy | Terms & Conditions