- Visit our CNC Machining & Laser Cutting Website:

- T2K CNC

- +44 (0) 121 242 2000

- sales@tooling2000.co.uk

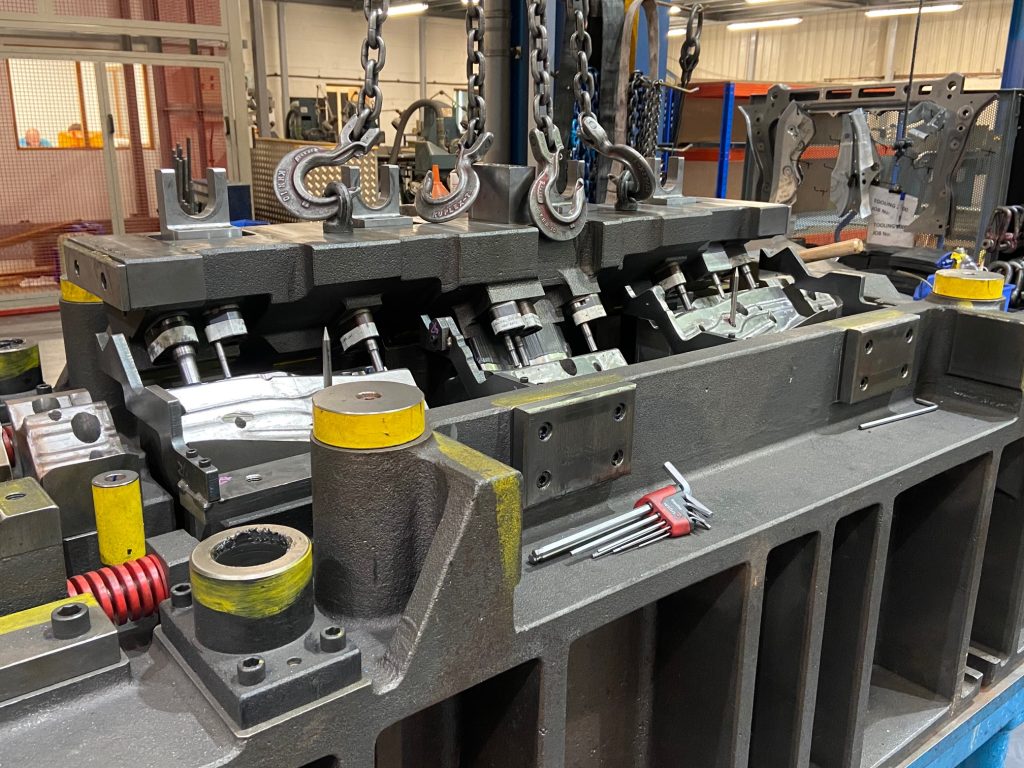

We deliver presswork for manufacturers who need consistent parts, predictable output, and dependable delivery. Our presswork is backed by in-house tooling expertise and a structured try-out approach, so production stays stable over repeat runs.

We support customers from early review through to repeat production, helping you avoid the usual presswork problems such as variation, tool wear issues, and unnecessary downtime. By keeping tooling close to production, we can respond quickly when tools need adjustment, repair, or modification, and we can maintain control over the details that affect part quality.

From complex projects to high-volume production, our tailored services ensure unmatched quality and reliability.

We support a wide range of presswork requirements, including repeat-stamped components and formed parts. We also support different tooling approaches, depending on the part and volumes.

Yes. Tooling support sits alongside our presswork capability, which helps us maintain control over repeatability, quality, and lead times.

We commonly work with stainless steel, aluminium, and brass. If you have a different material, share the details and we’ll confirm suitability.

Yes. We support different volume requirements depending on the part, tooling route, and production set-up. We’ll advise the best approach after reviewing your drawings and quantities.

Need repeatable presswork? Let’s keep it stable.

Tooling 2000 supports manufacturers who need consistent parts, predictable output, and dependable delivery – with presswork backed by in-house tooling support to reduce variation, downtime, and tool-wear issues over repeat runs.

Get in touch today – let’s keep your presswork running smoothly.

41 Western Road Winson Green Birmingham B18 7QD

sales@tooling2000.co.uk

+44 (0) 121 242 2000

© 2025 Tooling 2000 Ltd | Registered in England No. 03273596 | VAT Reg. No. GB195384370 | Privacy Policy | Terms & Conditions